Motivation and Applications

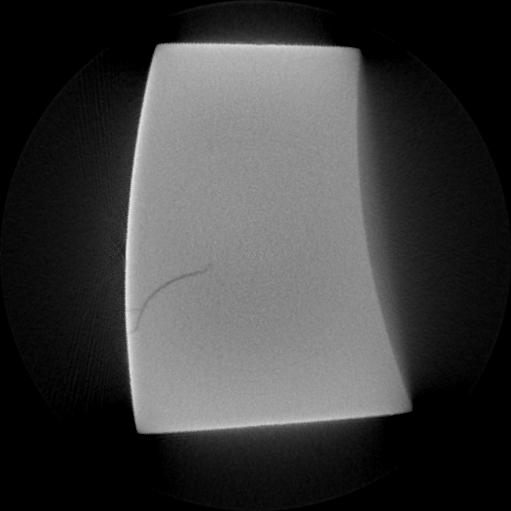

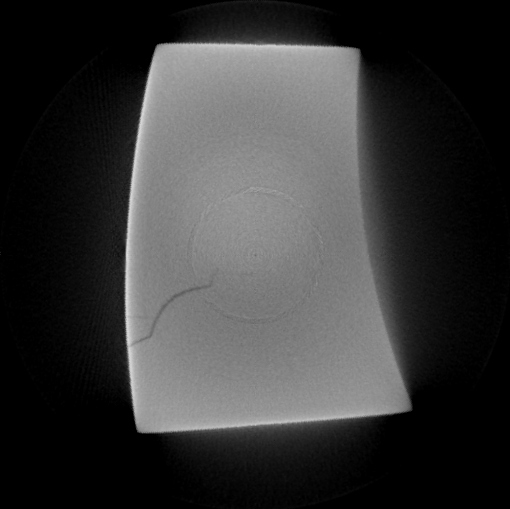

X-ray Computed Tomography enjoys rapidly growing interest in industrial quality inspection. However, to take advantage of this technique in the automated manufacturing process, one has to employ robust image processing algorithms that perform inspection tasks without human interaction. The pictures below show typical applications of industrial CT: the detection of defects such as pores, lunkers and cracks in a variety of parts.

|

|

State of related research and remaining challenges

While conventional 2D image processing is already widely applied in industry, methods for handling volume data have mainly been developed in the field of medical research, where data have different properties and automation is usually not an issue. To be used in industrial manufacturing, however, algorithms have to run fully automatically and work reliably on low-contrast noisy images characteristic of X-ray CT-data.

Methods

Basically we classify structures as defect, that cannot be described by our statistical model of the data. The data are modeled as locally homogeneous. Before the classification we enhance relevant structures using regularized derivative operators. In a final step we threshold the data based on the signal to noise ratio. Additional morphological operators are used to distinguish between constructive structures and defects.

|

|